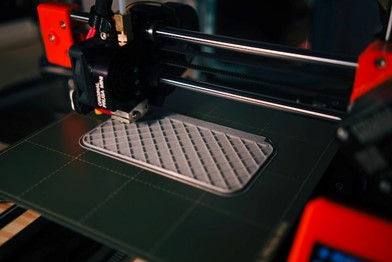

Lucciano Pascucci of Oxford Township has worked in aerospace and nuclear defense for over ten years. Aerospace has always been at the forefront of innovation, and with the development of 3D printing, also known as additive manufacturing, it has been a game changer in the industry. In the following article, Lucciano Pascucci discusses how 3D printing has revolutionized product designs among various industries and how businesses can incorporate 3D printing into practice.

In 2023, tech-minded strategies stand at the forefront of change development for forward-thinking businesses. Companies focused on product development must therefore consider the role of 3D printing in their procedures, but this requires keen understanding of both the benefits and stages of its implementation.

Lucciano Pascucci of Oxford Township says that not only does 3D printing streamline the process of developing prototypes and customizing products to meet consumer tastes, but it also plays a vital role in reducing costs and project risks by allowing for in-house resource production. To best incorporate 3D printing into product development, businesses should spend 75% of their focus on design and planning.

Before diving into more complicated topics such as risk reduction and stages of incorporation, it helps for companies to consider their purpose for embracing additive manufacturing as a product design strategy by considering the general benefits of its adoption.

Of course, streamlining these processes does not fully eliminate project risks. Fortunately, Lucciano Pascucci of Oxford Township says that 3D printing can reduce at least some risks on its own when utilized effectively.

First, designers no longer need to source essential resources such as tools and simple metal parts from third-party providers. Those that previously developed such reserves through traditional means of in-house production can cut down on time and costs. This alleviates a great deal of the risk involved when it comes to potential part shortages or broken tools.

Second, Lucciano Pascucci says that quality assurance through the use of prototypes becomes much more expedient when 3D printing is involved. When the production team identifies design flaws in a prototype, they no longer need to worry about long delays while developing a new model. Instead, they simply adjust their designs and print new prototypes with relative ease.

Even so, Lucciano Pascucci explains that companies that try to over-exploit these benefits will ultimately lose them in the long run. Printing new prototypes, for instance, will not save time or money when done recklessly and frequently without proper attention to the design phase. To this end, businesses choosing to make use of additive manufacturing will need to properly restructure their development process.

Incorporating 3D Printing into Business Practices

Incorporating 3D Printing into Business Practices